Our Capabilities

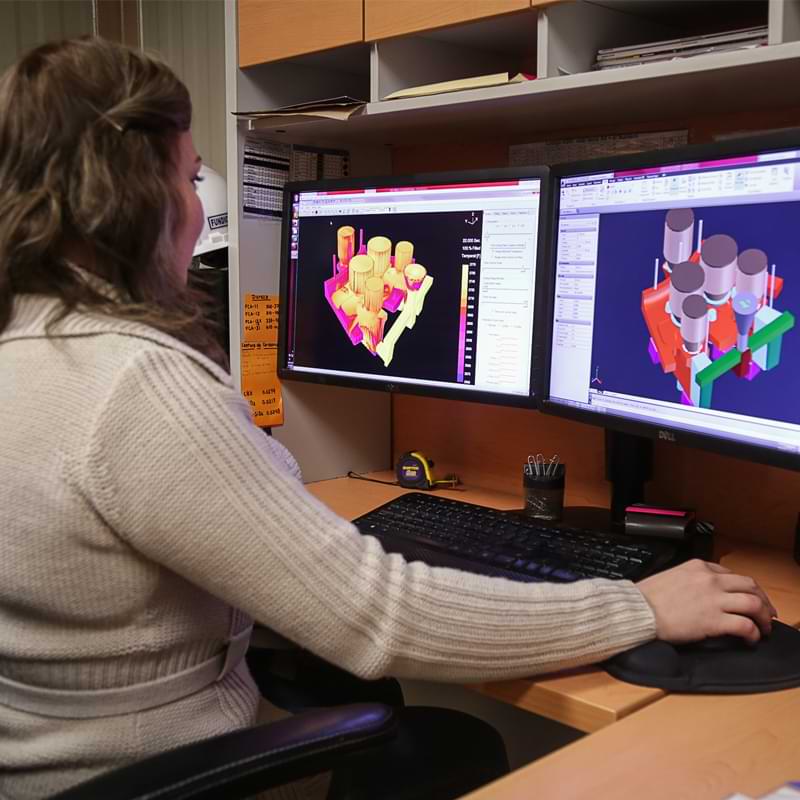

Over many years, FC Casting Solutions has streamlined our design and manufacturing approach to offer you fast, effective product development and manufacturing services.

We employ collaborative design, expert metallurgy, rapid prototyping, agile manufacturing, precision heat treatment capabilities and a keen focus on quality to deliver on our promise of being a reliable product development and production partner.

Excellent Quality

Our focus on quality in dimensional, material, and mechanical properties ensure that our castings meet or exceed your performance requirements.

We continuously look for ways to simplify and accelerate our manufacturing process without compromising quality. This keeps our lead times short, allowing you to reduce inventories and free up cash.

Our Capabilities

Get in touch today